Keyboard: + zoom in, - zoom out, 0 reset

Compatible Accessories & Holders

Specifications

Material & Construction

Material: High-grade steel, Accuracy: High precision, Finish: Fine balanced for high-speed, Balancing: Fine balanced

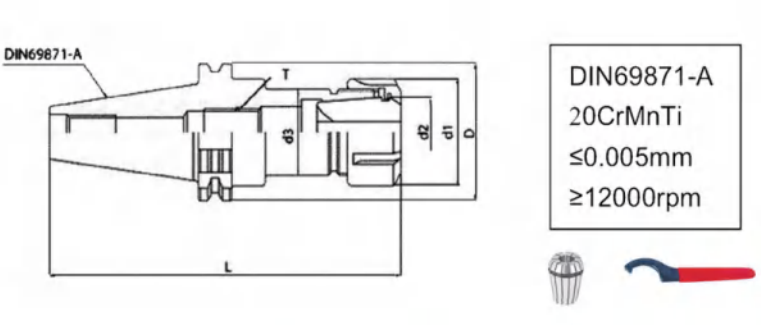

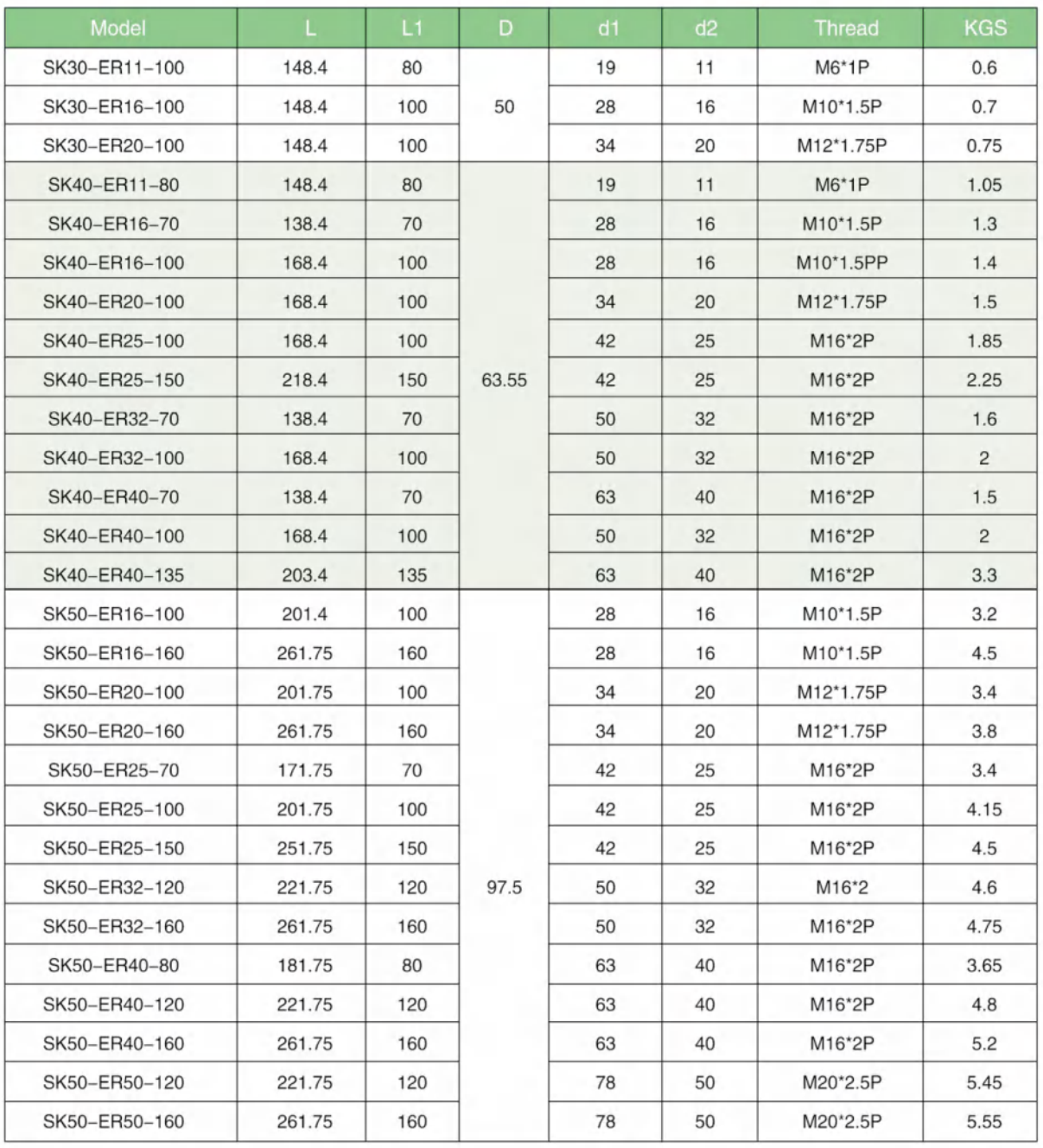

SK Type High-Speed & Fine Balanced Tool Holders

SK Type High-Speed & Fine Balanced Tool Holders **TAPER TYPE: SK (DIN 69871) - German/European Standard** AVAILABLE CONFIGURATIONS: ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ SK Taper Sizes: • SK30 - For smaller machining centers • SK40 - Most common European size (equivalent to BT40) • SK50 - Heavy duty machines ER Collet Sizes: ER11, ER16, ER20, ER25, ER32, ER40, ER50 Gauge Lengths (L1): 70mm, 80mm, 100mm, 120mm, 135mm, 150mm, 160mm ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ HOW TO ASSEMBLE: 1. Insert the SK holder into machine spindle 2. Select correct ER collet for your tool diameter 3. Place collet into holder nose 4. Insert cutting tool into collet 5. Thread on ER nut and tighten with spanner WHAT FITS WITH WHAT: • SK30 + ER11/ER16/ER20 - Small tools 1-13mm • SK40 + ER16/ER20/ER25/ER32/ER40 - Tools 1-26mm (most versatile) • SK50 + ER32/ER40/ER50 - Large tools 2-34mm COLLET SIZE SELECTION GUIDE: ┌─────────┬──────────────────┬─────────────────────────┐ │ ER Size │ Clamping Range │ Recommended For │ ├─────────┼──────────────────┼─────────────────────────┤ │ ER11 │ 1-7mm │ Small drills, engravers │ │ ER16 │ 1-10mm │ General small tools │ │ ER20 │ 1-13mm │ Most common drills │ │ ER25 │ 2-16mm │ Medium end mills │ │ ER32 │ 2-20mm │ Standard end mills │ │ ER40 │ 3-26mm │ Large end mills │ │ ER50 │ 4-34mm │ Heavy duty tools │ └─────────┴──────────────────┴─────────────────────────┘ REQUIRED ACCESSORIES: • ER Collets (matching size) • ER Nut (matching thread) • ER Spanner (for tightening) Price Range: €38.26 - €93.67

Select Specifications

φ(d)=Cutting Diameter | R=Radius | D=Shank Diameter | I=Cutting Length | L=Overall Length | All in mm

D=Diameter | L1, L2, L3=Length Dimensions | L=Overall Length | D1=Shank Diameter | All in mm

Select blade width, groove depth (T), and working radius range to find the right Face Groove tool

Select boring diameter range, shank diameter (D), and insert type (C=diamond/T=triangular) to find the right boring head

Select CBA model (complete boring range) and internal boring range to find the right micro finish boring head

Select LBK model (matches your CBA boring head) and extension length to find the right extension rod

Select BT type (spindle taper), LBK number (locking block socket), CBA head model, and projection length (L1) to find the right boring head shank

HRC≤56 is recommended for best price/performance ratio with newest nano-black coating technology.

No variants match the selected filters.

Try adjusting your filter selections.

No variants match the selected filters.

Try adjusting your filter selections.

SKU / Article Number

D (Diameter)

L1

L2

L3

L (Overall)

D1

Insert Code

Insert Count

h

b

H

F

L

L1

f

Insert

Blade Width

Blade Height

Groove Depth

Orientation

Working Radius Range

Compatible Inserts

φ(d)

R

D

I

L

Morse #

H7 Tolerance

Login to Purchase

Sign in to see prices, stock availability, and add items to your cart.

Please select specifications above to see details