Keyboard: + zoom in, - zoom out, 0 reset

Compatible Accessories & Holders

Specifications

Material & Construction

Material: High-grade steel, Accuracy: High precision, Finish: Hardened and ground

ER Collets extension Bars

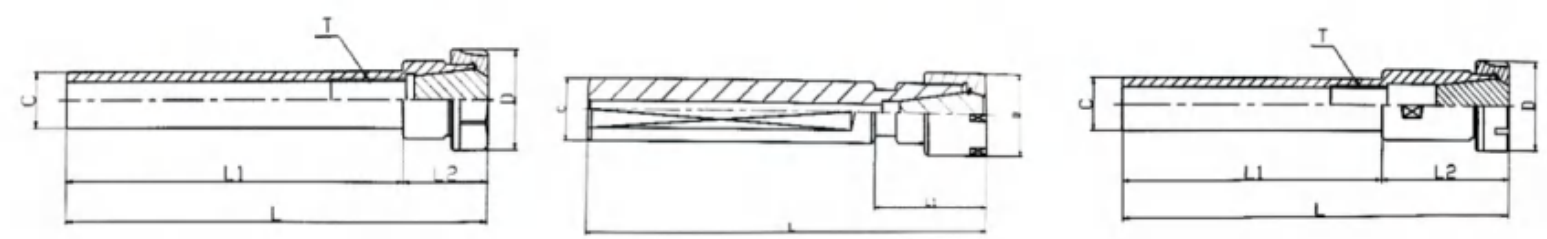

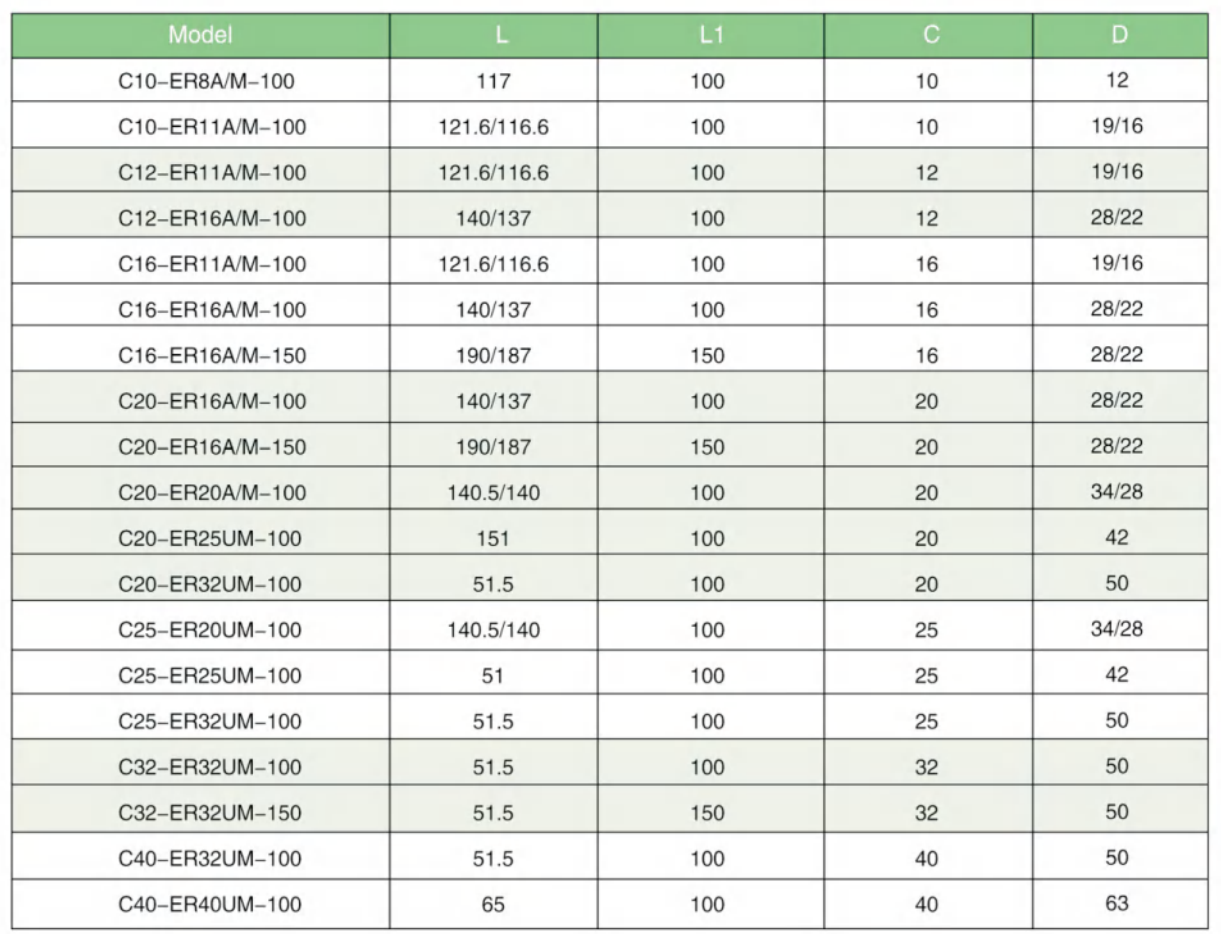

ER Collets Extension Bars - Extended Reach Solutions **TYPE: Extension bars for reaching deep cavities** AVAILABLE CONFIGURATIONS: ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ C-Holder Input Sizes: C10, C12, C16, C20, C25, C32, C40 ER Collet Output: ER8, ER11, ER16, ER20, ER25, ER32, ER40 Extension Lengths (L1): 100mm, 150mm Types: A (standard), M (mini), UM (ultra mini) ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ HOW EXTENSION BARS WORK: Extension bars have a C-shank (straight cylindrical) that mounts into a C-holder or side-lock chuck, and an ER collet output for your tool. ASSEMBLY SEQUENCE: 1. Mount C-holder/side-lock into your main tool holder (BT, SK, HSK) 2. Insert extension bar C-shank into C-holder 3. Lock with side screw 4. Insert ER collet into extension bar output 5. Insert cutting tool and tighten ER nut WHEN TO USE: ✓ Deep pocket milling ✓ Mold and die work ✓ Deep cavity finishing ✓ When standard holder length is insufficient ⚠️ IMPORTANT NOTES: • Use SHORTEST extension that provides clearance • Reduce speeds/feeds with longer extensions • Check runout increases with extension length • Maximum recommended total length depends on tool diameter WHAT FITS WITH WHAT: • C10 holder → ER8, ER11 output (very small tools) • C12 holder → ER8, ER11, ER16 output • C16 holder → ER11, ER16 output • C20 holder → ER16, ER20 output • C25 holder → ER20, ER25 output • C32 holder → ER25, ER32 output • C40 holder → ER32, ER40 output REQUIRED ACCESSORIES: • C-Holder or Side Lock Chuck (matching C size) • ER Collets (matching output size) • ER Nut • Main tool holder (BT, SK, HSK) 29 variants available | Price: €9.30 - €28.83

Select Specifications

φ(d)=Cutting Diameter | R=Radius | D=Shank Diameter | I=Cutting Length | L=Overall Length | All in mm

D=Diameter | L1, L2, L3=Length Dimensions | L=Overall Length | D1=Shank Diameter | All in mm

Select blade width, groove depth (T), and working radius range to find the right Face Groove tool

Select boring diameter range, shank diameter (D), and insert type (C=diamond/T=triangular) to find the right boring head

Select CBA model (complete boring range) and internal boring range to find the right micro finish boring head

Select LBK model (matches your CBA boring head) and extension length to find the right extension rod

Select BT type (spindle taper), LBK number (locking block socket), CBA head model, and projection length (L1) to find the right boring head shank

HRC≤56 is recommended for best price/performance ratio with newest nano-black coating technology.

No variants match the selected filters.

Try adjusting your filter selections.

No variants match the selected filters.

Try adjusting your filter selections.

SKU / Article Number

D (Diameter)

L1

L2

L3

L (Overall)

D1

Insert Code

Insert Count

h

b

H

F

L

L1

f

Insert

Blade Width

Blade Height

Groove Depth

Orientation

Working Radius Range

Compatible Inserts

φ(d)

R

D

I

L

Morse #

H7 Tolerance

Login to Purchase

Sign in to see prices, stock availability, and add items to your cart.

Please select specifications above to see details