Keyboard: + zoom in, - zoom out, 0 reset

Compatible Accessories & Holders

Specifications

Material & Construction

Material: 20CrMnTi, Balance: ≤0.005mm, Max Speed: ≥12000rpm

Understanding ER Collet Grades: "A" vs "UM"

The letter suffix on ER collets (like ER20A or ER32UM) indicates the precision grade and balancing quality of the collet system.

Standard Grade

Reliable precision for everyday machining

- Precision Level: Standard runout tolerance (typically ≤0.008mm)

- Speed Rating: Suitable for speeds up to 12,000-15,000 RPM

- Applications: General machining, drilling, roughing operations

- Cost: Most economical option - excellent value for standard work

Ultra-precision, Micro-balanced

Premium grade for high-speed and finishing work

- Precision Level: Superior concentricity with runout <0.003mm (often <0.002mm)

- Speed Rating: Dynamically balanced for high-speed operations (20,000-30,000+ RPM)

- Applications: Finishing operations, high-speed milling, precision boring, micro-machining

- Benefits: Extended tool life, superior surface finish, reduced vibration at high RPM

Selection Tip: Choose A-grade for general-purpose work and cost efficiency. Upgrade to UM-grade when you need exceptional surface finish, tight tolerances, or are running high-speed operations above 15,000 RPM.

Tool Holder Type Guide

Different types (A, B, C, D, E) represent variations in material quality, precision grade, and speed capability to match your application requirements.

| Type | Material | Precision | Speed Rating | Best For |

|---|---|---|---|---|

| A | Standard Steel | Standard (General use) |

≤12,000 RPM | General machining, conventional operations |

| B | Heat-Treated Alloy | High (Tighter tolerances) |

≤15,000 RPM | Precision machining, better surface finish |

| C | Premium Alloy | High Precision (Low runout) |

≤18,000 RPM | High-speed operations, fine finish work |

| D | Hardened Alloy | Ultra Precision (Minimal runout) |

≤20,000 RPM | High-precision aerospace, mold making |

| E | Special Coating | Standard+ (Corrosion resistant) |

≤12,000 RPM | Harsh environments, extended tool life |

Recommendation: Type A (Standard) is used in most industrial applications and is suitable for general machining operations. Choose Type A if you're unsure about your specific requirements - it provides excellent performance for the majority of CNC work.

Note: All types share the same physical dimensions. The variation is in material quality, manufacturing precision, and dynamic balancing specifications.

BT x ER Tool Holders

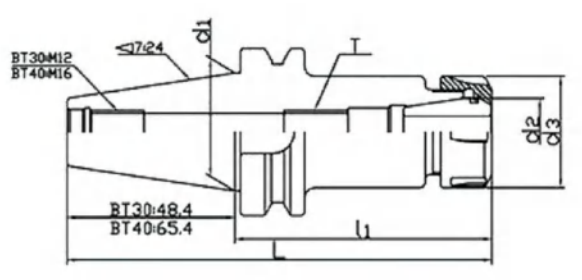

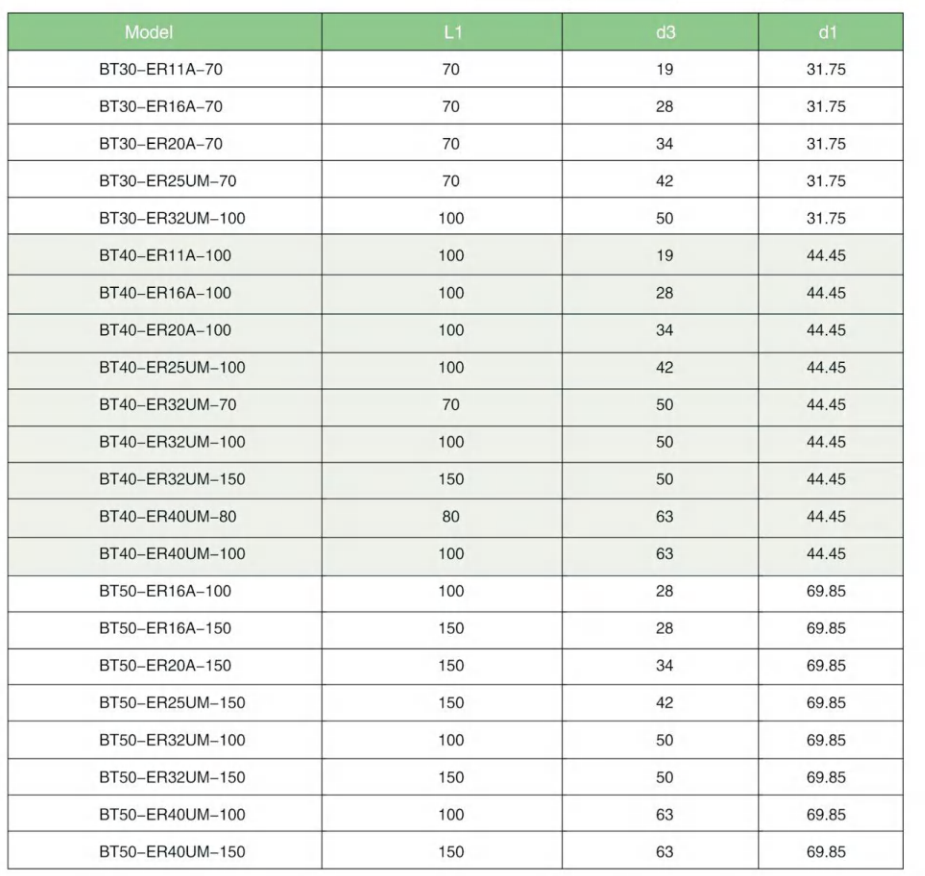

BT x ER Tool Holders - The Most Popular CNC Tool Holding System **TAPER TYPE: BT (MAS 403 / JIS B 6339) - International Standard** AVAILABLE CONFIGURATIONS: ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ BT Taper Sizes: • BT30 - Small VMC (flange Ø31.75mm) • BT40 - Most popular size (flange Ø44.45mm) • BT50 - Heavy duty (flange Ø69.85mm) ER Collet Sizes: ER11A, ER16A, ER20A, ER25UM, ER32UM, ER40UM Gauge Lengths (L1): 70, 80, 100, 150, 200, 250, 300, 350, 400, 450, 500mm Pull Stud Types: A, B, C, D, E (machine specific - check your machine!) ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ ⚠️ IMPORTANT - PULL STUD TYPES: Different machines require different pull stud (retention knob) types: • Type A - Mazak, Okuma, Makino, Mori Seiki • Type B - Fanuc, Brother, Kitamura • Type C - Haas, Fadal • Type D - Hurco • Type E - Doosan, Hyundai **CHECK YOUR MACHINE MANUAL BEFORE ORDERING!** HOW TO ASSEMBLE: 1. Screw retention knob (pull stud) into BT holder 2. Insert holder into machine spindle (ATC or manual) 3. Select ER collet matching your tool shank diameter 4. Insert collet into holder taper 5. Insert cutting tool into collet 6. Thread ER nut and tighten with spanner (25-35 Nm) WHAT FITS WITH WHAT: • BT30 machines → BT30-ER11A to BT30-ER32UM • BT40 machines → BT40-ER11A to BT40-ER40UM (most common) • BT50 machines → BT50-ER25UM to BT50-ER40UM LENGTH SELECTION GUIDE: • L1=70-100mm: Standard operations, maximum rigidity • L1=150-200mm: Extended reach, moderate depth • L1=250-350mm: Deep pockets, cavities • L1=400-500mm: Very deep reach (use with caution - less rigid) RECOMMENDATION: Use shortest length that allows clearance! REQUIRED ACCESSORIES: • Retention Knob (Pull Stud) - MUST match machine type • ER Collets (A or UM type) • ER Nut • ER Spanner 260 variants available | Price: €21.39 - €256.68

Select Specifications

φ(d)=Cutting Diameter | R=Radius | D=Shank Diameter | I=Cutting Length | L=Overall Length | All in mm

D=Diameter | L1, L2, L3=Length Dimensions | L=Overall Length | D1=Shank Diameter | All in mm

Select blade width, groove depth (T), and working radius range to find the right Face Groove tool

Select boring diameter range, shank diameter (D), and insert type (C=diamond/T=triangular) to find the right boring head

Select CBA model (complete boring range) and internal boring range to find the right micro finish boring head

Select LBK model (matches your CBA boring head) and extension length to find the right extension rod

Select BT type (spindle taper), LBK number (locking block socket), CBA head model, and projection length (L1) to find the right boring head shank

HRC≤56 is recommended for best price/performance ratio with newest nano-black coating technology.

No variants match the selected filters.

Try adjusting your filter selections.

No variants match the selected filters.

Try adjusting your filter selections.

SKU / Article Number

D (Diameter)

L1

L2

L3

L (Overall)

D1

Insert Code

Insert Count

h

b

H

F

L

L1

f

Insert

Blade Width

Blade Height

Groove Depth

Orientation

Working Radius Range

Compatible Inserts

φ(d)

R

D

I

L

Morse #

H7 Tolerance

Login to Purchase

Sign in to see prices, stock availability, and add items to your cart.

Please select specifications above to see details