Keyboard: + zoom in, - zoom out, 0 reset

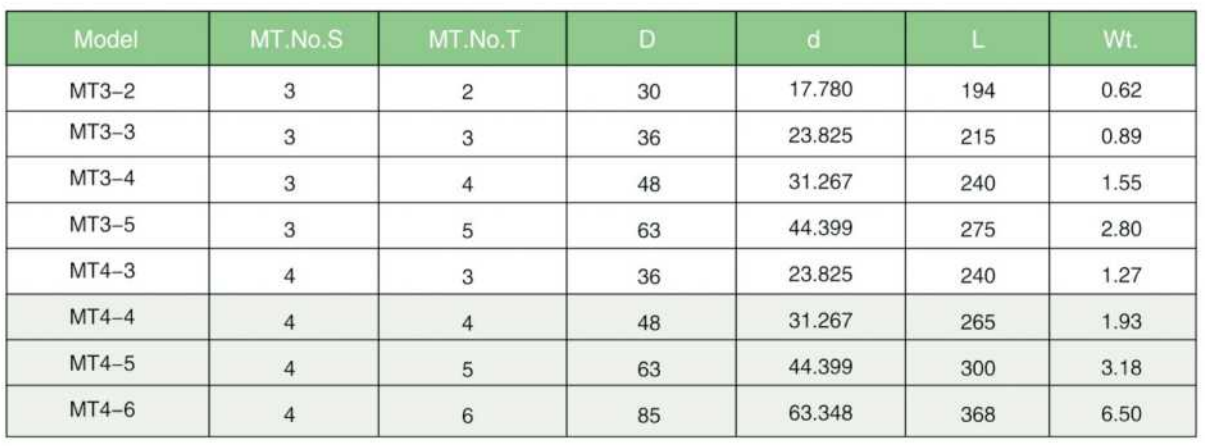

Specifications

Material & Construction

Material: Alloy Steel, Interface: Morse Taper Extension Sleeve, Hardness: HRC48-52

How to Choose Your Extension Drill Sleeve

Model Format: MT[Socket]-[Tang]

Socket Size (First Number)

The Morse Taper size of your machine spindle (what the extension sleeve fits into)

Tang Size (Second Number)

The Morse Taper size of your tool (what tool the extension sleeve accepts)

Key Difference: Extension Length

Extension sleeves are longer than standard sleeves, providing both taper adaptation AND extended reach for deep hole drilling operations.

Example

MT3-2 means:

- MT3 Socket - Fits into your machine with MT3 spindle

- MT2 Tang - Accepts tools with MT2 taper

- Extended Length - Provides additional reach (L=194mm)

How to Choose:

- Check your machine spindle Morse Taper size (MT3, MT4, etc.)

- Check your tool's Morse Taper size

- Determine if you need extended reach for deep hole drilling

- Select the model: MT[machine]-[tool]

Note: Extension sleeves can accept tools with equal or smaller taper sizes. Use MT3-3 for equal sizes with extended length, or MT3-2/MT4-3 for reduction with extension.

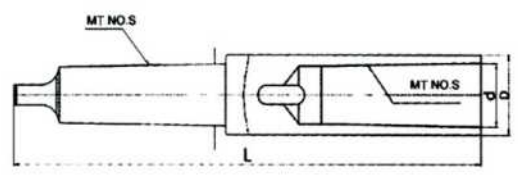

Extension Drill Sleeves

Extension Drill Sleeves combine the functionality of a taper adapter with extended length, allowing both size reduction and reach extension in a single component. Available in MT3 and MT4 socket sizes with various tang configurations (MT2, MT3, MT4, MT5, MT6). These extension sleeves provide excellent concentricity and secure tool holding while extending your tool reach. Ideal for deep hole drilling operations where additional length is needed. The hardened and ground construction ensures long-lasting accuracy and reliability.

Select Specifications

φ(d)=Cutting Diameter | R=Radius | D=Shank Diameter | I=Cutting Length | L=Overall Length | All in mm

D=Diameter | L1, L2, L3=Length Dimensions | L=Overall Length | D1=Shank Diameter | All in mm

Select blade width, groove depth (T), and working radius range to find the right Face Groove tool

Select boring diameter range, shank diameter (D), and insert type (C=diamond/T=triangular) to find the right boring head

Select CBA model (complete boring range) and internal boring range to find the right micro finish boring head

Select LBK model (matches your CBA boring head) and extension length to find the right extension rod

Select BT type (spindle taper), LBK number (locking block socket), CBA head model, and projection length (L1) to find the right boring head shank

HRC≤56 is recommended for best price/performance ratio with newest nano-black coating technology.

No variants match the selected filters.

Try adjusting your filter selections.

No variants match the selected filters.

Try adjusting your filter selections.

SKU / Article Number

D (Diameter)

L1

L2

L3

L (Overall)

D1

Insert Code

Insert Count

h

b

H

F

L

L1

f

Insert

Blade Width

Blade Height

Groove Depth

Orientation

Working Radius Range

Compatible Inserts

φ(d)

R

D

I

L

Morse #

H7 Tolerance

Login to Purchase

Sign in to see prices, stock availability, and add items to your cart.

Please select specifications above to see details