Keyboard: + zoom in, - zoom out, 0 reset

Compatible ER Collet Accessories

Specifications

Material & Construction

Material: 65Mn, Hardness: HRC44-48, Coolant Pressure: 7MPa

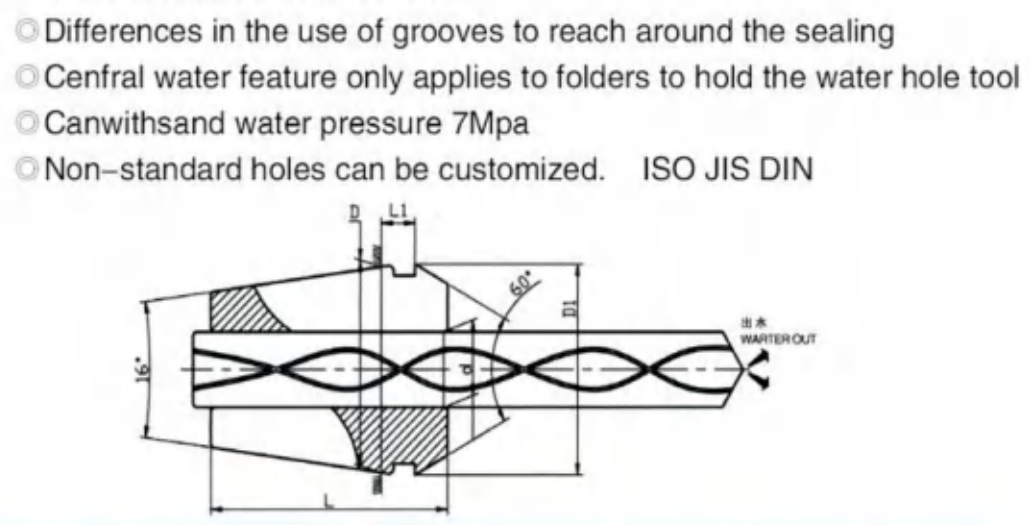

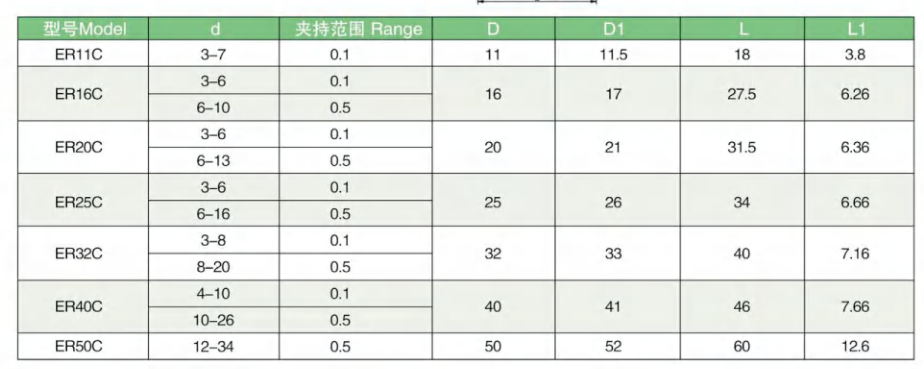

ER/C Collet (Oil Hole Type)

ER/C Collets (Oil Hole Type) - Through-Coolant Collets **SPECIAL COLLET - Internal coolant passage for better chip evacuation** ER/C collets have an internal coolant hole that allows cutting fluid to flow through the collet and out through the tool (if tool has internal coolant). WHY USE COOLANT-THROUGH COLLETS: ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ ✓ Better chip evacuation (especially in deep holes) ✓ Improved tool life ✓ Better surface finish ✓ Essential for internal coolant drills ✓ Reduced heat at cutting edge ━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━ AVAILABLE SIZES: ┌──────────┬───────────────┬─────────────────────────┐ │ ER/C Size│ Clamping Range│ Typical Tools │ ├──────────┼───────────────┼─────────────────────────┤ │ ER11C │ 3-7mm │ Small coolant drills │ │ ER16C │ 3-10mm │ Common coolant drills │ │ ER20C │ 3-13mm │ Medium drills/taps │ │ ER25C │ 3-16mm │ Standard drills │ │ ER32C │ 3-20mm │ Large drills (popular) │ │ ER40C │ 4-26mm │ Heavy duty drills │ │ ER50C │ 12-34mm │ Large diameter drills │ └──────────┴───────────────┴─────────────────────────┘ REQUIREMENTS: • Tool holder with through-coolant capability • Machine with coolant-through-spindle (CTS) • Cutting tools with internal coolant holes HOW IT WORKS: 1. Coolant enters spindle 2. Flows through tool holder center 3. Passes through ER/C collet center hole 4. Exits through tool's internal passages 5. Reaches cutting edge directly! COMPATIBLE WITH: • BT-ER Tool Holders (with CTS) • HSK-A-ER Tool Holders (standard CTS) • Through-coolant straight shank holders • Internal coolant drills (HM drills with coolant) • ER Nuts (standard type) BEST FOR: • Deep hole drilling • Production drilling • Stainless steel machining • Difficult materials 95 variants | Price: €8.65 - €31.62

Internal Coolant System

Equipped with internal coolant channels for enhanced cooling

Select Specifications

φ(d)=Cutting Diameter | R=Radius | D=Shank Diameter | I=Cutting Length | L=Overall Length | All in mm

D=Diameter | L1, L2, L3=Length Dimensions | L=Overall Length | D1=Shank Diameter | All in mm

Select blade width, groove depth (T), and working radius range to find the right Face Groove tool

Select boring diameter range, shank diameter (D), and insert type (C=diamond/T=triangular) to find the right boring head

Select CBA model (complete boring range) and internal boring range to find the right micro finish boring head

Select LBK model (matches your CBA boring head) and extension length to find the right extension rod

Select BT type (spindle taper), LBK number (locking block socket), CBA head model, and projection length (L1) to find the right boring head shank

HRC≤56 is recommended for best price/performance ratio with newest nano-black coating technology.

No variants match the selected filters.

Try adjusting your filter selections.

No variants match the selected filters.

Try adjusting your filter selections.

SKU / Article Number

D (Diameter)

L1

L2

L3

L (Overall)

D1

Insert Code

Insert Count

h

b

H

F

L

L1

f

Insert

Blade Width

Blade Height

Groove Depth

Orientation

Working Radius Range

Compatible Inserts

φ(d)

R

D

I

L

Morse #

H7 Tolerance

Login to Purchase

Sign in to see prices, stock availability, and add items to your cart.

Please select specifications above to see details