Keyboard: + zoom in, - zoom out, 0 reset

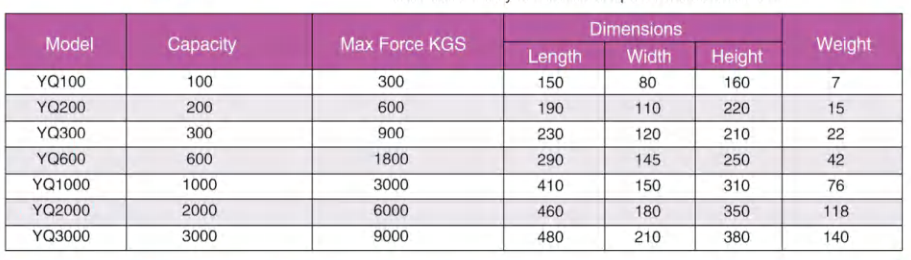

Specifications

Material & Construction

Material: High-performance magnetic material

Understanding Safety Factor & Lifting Capacity

3:1 Safety Factor Rating: These permanent magnetic lifters are engineered with a 3x safety margin for maximum reliability and safe operation.

Safe Working Load (SWL)

The Capacity rating (e.g., 100 kg, 300 kg, 1000 kg) represents the recommended safe working load for continuous, reliable operation with optimal safety margins.

Maximum Force (Peak Holding Power)

The Max Force KGS (shown in table) indicates the lifter's actual maximum magnetic holding force — typically 3 times the rated capacity. For example, a 100 kg capacity lifter has 300 KGS max force.

Example: A YQ100 model (100 kg capacity) can theoretically hold up to 300 kg maximum force, but is rated for safe continuous use at 100 kg to account for surface conditions, material variations, and dynamic forces during lifting operations.

Safety Recommendation: Always operate within the rated Capacity (not Max Force) to ensure safe lifting operations. The 3x safety factor provides protection against unexpected conditions such as surface irregularities, material thickness variations, air gaps, or dynamic loads during handling.

Classic Permanent magnetic Lifters

Permanent magnetic lifters use new type and high-performance magnetic material. They are characterized by smaller size and lighter weight, yet offer powerful lifting effort on any of residual lifting materials. Easy to operate, without electricity in operation, long period effort. These magnetic lifters have been used widely to lift and transport steel and iron materials in various industrial applications including workshops, docks, and warehouses.

Select Specifications

φ(d)=Cutting Diameter | R=Radius | D=Shank Diameter | I=Cutting Length | L=Overall Length | All in mm

D=Diameter | L1, L2, L3=Length Dimensions | L=Overall Length | D1=Shank Diameter | All in mm

Select blade width, groove depth (T), and working radius range to find the right Face Groove tool

Select boring diameter range, shank diameter (D), and insert type (C=diamond/T=triangular) to find the right boring head

Select CBA model (complete boring range) and internal boring range to find the right micro finish boring head

Select LBK model (matches your CBA boring head) and extension length to find the right extension rod

Select BT type (spindle taper), LBK number (locking block socket), CBA head model, and projection length (L1) to find the right boring head shank

HRC≤56 is recommended for best price/performance ratio with newest nano-black coating technology.

No variants match the selected filters.

Try adjusting your filter selections.

No variants match the selected filters.

Try adjusting your filter selections.

SKU / Article Number

D (Diameter)

L1

L2

L3

L (Overall)

D1

Insert Code

Insert Count

h

b

H

F

L

L1

f

Insert

Blade Width

Blade Height

Groove Depth

Orientation

Working Radius Range

Compatible Inserts

φ(d)

R

D

I

L

Morse #

H7 Tolerance

Login to Purchase

Sign in to see prices, stock availability, and add items to your cart.

Please select specifications above to see details